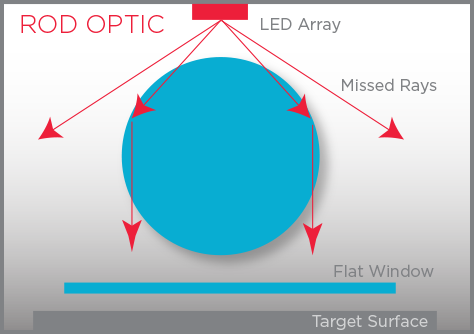

UV curing systems using UV LED arrays without an optical element frequently allow light rays to miss the curing surface. This wasted energy leads to increased operating costs. Conversely, an optimized system will direct the bulk of UV rays to the intended surface.

UV curing systems using UV LED arrays without an optical element frequently allow light rays to miss the curing surface. This wasted energy leads to increased operating costs. Conversely, an optimized system will direct the bulk of UV rays to the intended surface.

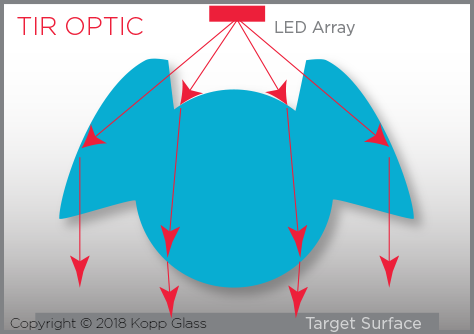

Kopp found that by introducing an optimized UV glass optic, the efficiency of a UV curing system can be improved. In our case study “The Effects of UV Glass Optics on UV LED Arrays,” we performed an optical simulation on both the commonly used fused quartz rod optic and a UV transmitting borosilicate Total Internal Reflection (TIR) optic.

The study demonstrates that compared to a UV LED array without an optic, both the rod and TIR optics increase peak irradiance and refract more energy toward the curing target surface. While both optic types have their own unique advantages and disadvantages, the results are clear in demonstrating that UV glass TIR optics are more efficient at capturing stray rays of light and increasing peak irradiance. By adding this optical element, you can control the collimation of the light beam and the irradiance pattern at the measurement surface, which results in a higher-performance UV LED curing system.

Kopp Glass recently presented this investigation into LED array efficiency to industry professionals at the RadTech UV+EB Technology Conference in Rosemont, Illinois. The technical paper and companion presentation are now available for public download. We hope our research can assist in the successful optimization of UV LED curing systems.

Click here to download our study “The Effects of UV Glass Optics on UV LED Arrays."